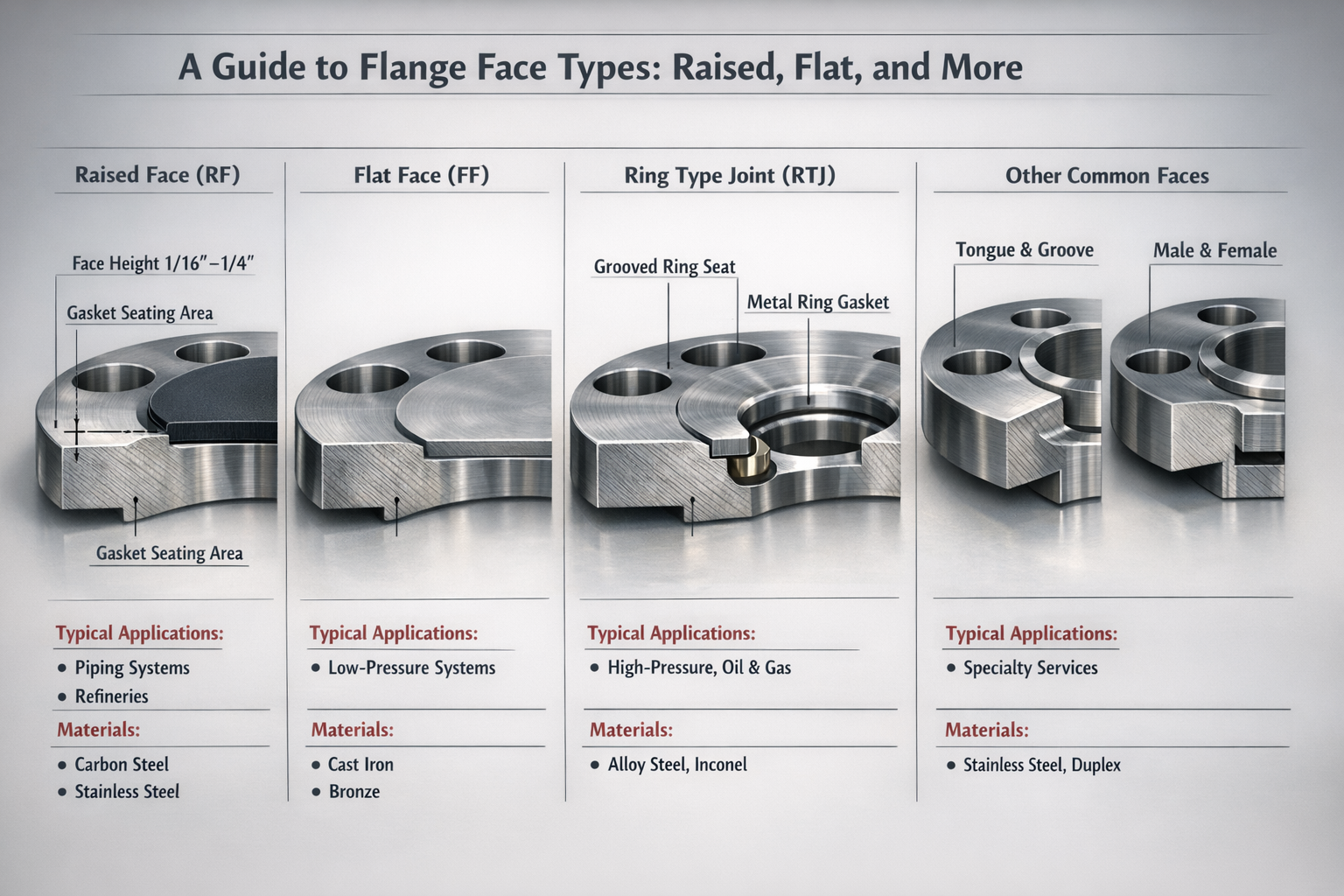

The face of a flange is its sealing surface. It is the part that touches the gasket. The type of face you choose is critical. It determines how well the seal works, what gasket to use, and what pressure the joint can handle. This guide explains the common types: Raised Face, Flat Face, and others.

Quick Comparison of Flange Face Types

This table summarizes the key features of the most common flange faces.

| Face Type | Description | Typical Applications | Gasket Type |

| Raised Face (RF) | A raised ring around the bore. Common in ASME standards. | Most common for industrial steel piping. Used for moderate to high pressure. | Ring Gasket (inside the bolt circle). |

| Flat Face (FF) | A completely flat surface, level with the bolt holes. | Low-pressure systems, cast iron, plastic, or ductile iron equipment. | Full-Face Gasket (covers the entire face, including bolt holes). |

| Ring-Type Joint (RTJ) | Has a deep, precision-machined groove for a metal ring. | Very high-pressure and high-temperature services (e.g., oil & gas wellheads). | Oval or Octagonal Metal Ring Gasket. |

| Tongue and Groove (T&G) | One flange has a raised “tongue,” the other a matching “groove.” | Seals where gasket blow-out is a risk or for hard-to-hold fluids. | Flat Ring Gasket that fits in the groove. |

| Male and Female (M&F) | Similar to T&G but with different proportions. The male end fits into the female. | Often used for high-pressure valve bonnets and specialty connections. | Flat Ring Gasket that fits in the female face. |

Detailed Look at Common Face Types

Raised Face (RF)

The Raised Face is the standard for most industrial steel piping. The raised portion concentrates the bolt force onto a smaller gasket area. This creates a tighter seal. The height of the raised face is standardized. For ASME B16.5 Class 150 and 300 flanges, it is 1/16 inch (1.6 mm). For Class 600 and higher, it is 1/4 inch (6.4 mm). A common gasket for RF flanges is a spiral-wound gasket.

Flat Face (FF)

A Flat Face flange is exactly what it sounds like—the sealing surface is completely flat. The main reason to use an FF flange is to protect brittle materials. When you bolt two flanges together, the force is spread over the entire surface. This prevents cracking in materials like cast iron, ductile iron, or plastic. FF flanges always use a full-face gasket.

Important Note: You should never directly bolt an RF flange to an FF flange. The raised face creates a gap and puts bending stress on the FF flange, which can cause it to crack. If you need to connect them, you must machine off the raised face from the RF flange to create two flat surfaces.

Ring-Type Joint (RTJ)

RTJ faces are for extreme conditions. They have a groove that holds a solid metal ring gasket. When the bolts are tightened, the metal ring is compressed into the groove, forming a very strong, leak-proof seal. They are common in API 6A wellhead equipment and other high-pressure systems.

Tongue and Groove (T&G) & Male and Female (M&F)

These faces are used when you need precise alignment and extra protection against the gasket being blown out by internal pressure. The tongue or male section acts as a built-in gasket locator. They are often found in heat exchangers, pump covers, and for sealing hazardous fluids.

Frequently Asked Questions

Q: Is a “Full Face Flange” a type of flange face?

A: This term can be confusing. “Full face” usually refers to a gasket, not the flange face itself. A Full-Face Gasket is one that covers the entire flange surface and has holes for the bolts. It is the correct gasket to use with a Flat Face (FF) flange.

Q: How do I know which face type I have?

A: You can identify it visually and by measuring.

- RF: You will see and feel a raised ring.

- FF: The surface is completely flat to the touch across the whole diameter.

- RTJ: Look for a deep, machined groove.

Q: Can I use the same gasket for RF and FF flanges?

A: No. RF flanges use a ring gasket that sits inside the bolt circle. FF flanges require a full-face gasket. Using the wrong gasket will cause a leak.

Q: Are these face types interchangeable?

A: No, they are not. A Raised Face must mate with another Raised Face (with a ring gasket in between). A Flat Face must mate with another Flat Face (with a full-face gasket). Mixing them will not work and can damage the flanges.

Conclusion

Choosing the correct flange face type is a basic but critical step in designing a piping system. The face type must match the pressure, the flange material, and the type of gasket. Using the wrong combination is a common cause of leaks and joint failure.

Need help specifying the correct flange face type and compatible gasket for your pressure, temperature, and material requirements? Our technical team can ensure your connections are designed for safety and reliability.

Submit your project details for expert guidance and a quote: http://texasflange.com/lp12/